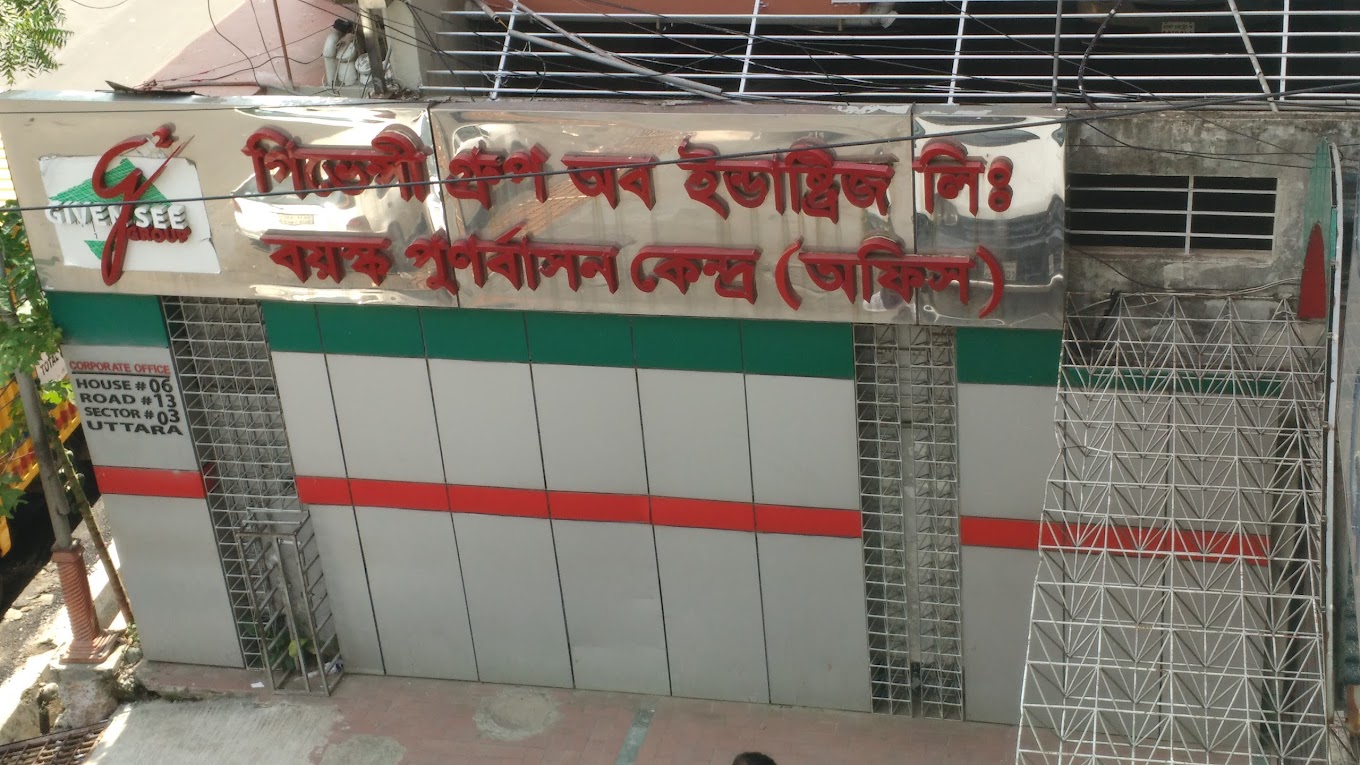

Social Activities: Old Rehabilitation Centre: As a part of discharging social responsibilities Khatib Abdul Zahid Mukul established Old Rehabilitation Center in 1987 on a rented premise on his own initiative and with his own finance with a view to mitigating the painful sufferings of helpless old people of 60 years and above who have no support other than the Almighty Allah. In 1994 the center was shifted to its own land of 72 bighas located at a calm and quiet place with the natural beauty of Bishia Kuribari, Monipur, Gazipur having a distance of about 40 KM from Uttara, Dhaka. On April 21, 1995, Nobel peace prize winner, Mother Teresa founded the stone of the expansion project of the center. Helpless people above 60 years are rehabilitated with full responsibility in the center. All basic amenities like accommodation, food, cloths, medicines, and other facilities are provided free of cost to the neglected, unable to earn a livelihood, and helpless old people above 60 years till their death in the center. At present, there are accommodation facilities for about 1200 old people in the center. The center does not obtain any sort of financial aid/assistance from outside either public, private, or govt., local or foreign. All expenses of the center are borne out of the income of Givensee Group of Industries Ltd. One rehabilitation center of the same nature has also been established at Katapahar (Bat-Tala), Tabalchari, Rangamati to facilitate old helpless people of 60 years and above of tribal areas having different modes of life, culture, religion from the rest part of the country who hesitate to move another place from their own.

.

Givensee Group of Industries Ltd. comprise of the following 9 industries:

1. Givensee Spinning Mills Ltd.:

It is the largest industrial unit of the Group that produces knit yarn from imported ginned raw cotton. It produces cheese/cone yarn of 6 – 20 counts as well as the combed and carded yarn of 20 – 40 counts. It is the backward linkage industry of knit composite garments and is 100%, deems an exporter.

2. Hotapara Garments Ltd.:

It is a 100% export-oriented composite knit garments industry. It undertakes

(i) fabrics knitting from knit yarn,

(ii) dyeing and finishing of knitted fabrics,

(iii) manufacturing of RMG through cutting and sewing of dyed fabrics, and

(iv) screen printing of RMG. The products of the industry include knit ready-made garments viz. T-shirts, Polo shirts, Tank tops, Vest, Jackets, etc.

3.Hotapara Garments Ltd.(Towel):

We have 120 brand-new Shuttle Looms and 30 brand-new Repair Shuttleless Looms in operation for producing quality towels. We have soft flow dyeing capacity and 10000 sft floors for finishing operation.

Weaving Capacity:

Shuttle Looms – 5000 Kg/Day

Repair Shuttleless Looms – 5000 Kg/Day

Dyeing Capacity – 12000 Kg/Day

Manpower – 820 Personnel

Products: All types of terry towels (From 300 – 700 GSM)

4. Zahintex Industries Ltd.:

It is a 100% export-oriented sweater manufacturing industry. It procures principal raw materials of dyed acrylic yarn from sister concern viz. Masuma Khatun Textile Industries Ltd. (a sweater yarn dyeing industry). It is equipped with about 6,000 hand-driven flat knitting machines of Taiwan and China ranging from 1.5 Gauge to 14 Gauge. Yearly Production Capacity is about 12.10 million pcs of different sizes. Besides, there are 30 sets of Jackard machines imported from Germany having a yearly production capacity of about 1.00 million pcs. At present Zahintex Industries Ltd. has a total production of about 9.50 million pcs per year and export of around Tk. 3250.00 million (US$ 40.00 million) per year.

5. Masuma Khatun Textile Industries Ltd.:

It is an acrylic and cotton yarn (for sweaters) dyeing industry. It is a backward linkage industry of sweaters. The industry is a 100% deemed exporter. It sells about 40% of its products of dyed yarn to sister concerns viz. Zahintex Industries Ltd. (a 100% export-oriented sweater manufacturing industry). Here yarn is dyed in hands/spray, cabinet, and piece method. The yearly production capacity of spray, cabinet, and piece dyeing of yarn is about 16.5 million lbs.

6. Givensee Garments Ltd.:

It is a 100% export-oriented denim woven RMG manufacturing industry. It is composed of a sewing unit and a washing plant. Woven ready-made garments of denim clothing like jeans pants, jeans jackets, jeans shirts/blouses, etc. are manufactured from imported denim (woven) fabrics.

7. Givensee Garments Accessories Ltd.:

The industry is engaged in the production of various items of garments and accessories. The main products of the industry are poly, corrugated cartons, sewing thread, embroidery, hang tags, off-set printing and press, metal zipper, printed level, oven level, gum tape, neck board, backboard, price tack, barcode stickers, etc. It is a backward linkage industry of garments; and as such 100% deemed exporter.

8. Recycling Project:

It is an extension project of Hotapara Garments Ltd. (100% export-oriented composite knit RMG). It is composed of a recycling plant, an open-end unit, and weaving – finishing unit. In recycling, unit cotton is manufactured from waste fabrics of the knit garments industry. Yarn is produced with this cotton in an open-end unit. Yarn of 6 to 16 count is manufactured having a yearly production capacity of 30.00 million lbs. Produced yarn is used in the weaving–finishing unit having a shuttle loom with dyeing and finishing facilities. All types of terry towels, (from 300 – 650 GSM) are produced in this unit with the yarn produced by the open-end unit. Terry towels are mainly exported to various countries in Europe and the USA.8.

Givensee Foods Ltd.:

It has been set up with a view to producing soymilk from soybean through modern technology. Subsequently, more food items have been added to the product mix of the industry through expansion with additional investment. The products of the industry are biscuits, bread, toast biscuits, bun, top cake, chanachur, chatni, shemai, puffed rice (muri), ground spices (chilly, turmeric, cumin, and coriander), mineral water etc. All these food items are sold locally as well as exported to countries of the Middle East, Europe, and the USA.

Direction

Direction 1,110

1,110 Check In

Check In

View Map

View Map Claim it

Claim it Online Scheduling

Online Scheduling